OptinJect is all-in-one control system specially developed for the automation of plastic processing machines, e.g. injection molding machines.

All-in-one means that: I/Os, control, visualization, networking and expandability are already present in to the OptinJect system. ULV (Ultra Low Voltage) CPUs integrated with particular cooling system without fans, allow the system to operate in harsh environment condition.

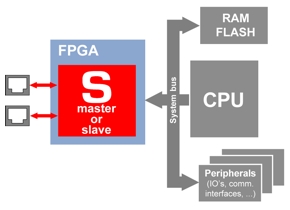

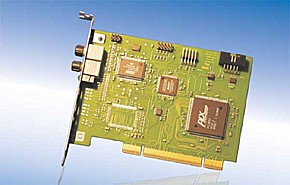

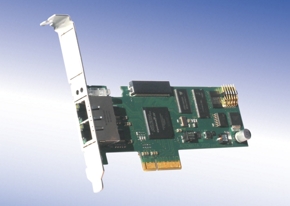

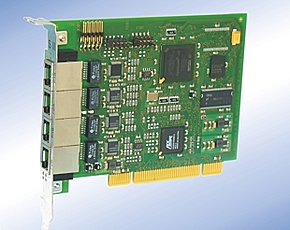

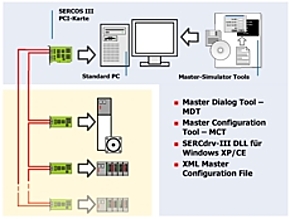

OptinJect is also a modular I/Os Control System with an optional CAN bus or Sercos III PCI board for standard I/O connections.

The Analog Interrupt capability with threshold (Injection Speed to holding pressure switch) and 3 fast counter 32 Bits (Screw RPM and Mould Adjust position) are developed in particular for injection molding machine.

The programming suite for OptinJect units is CoDeSys by 3S and. This powerful development tool with all IEC 61131-3 functions, soft motion, visualization (WinMachLite) and all other necessary features does ensure efficient and comfortable programming, running together with embedded operating systems Windows® CE.NET.

With knowledge and experience in industrial automation solutions, Cannon Automata focuses on programmable automation controller and fieldbus applications.

With knowledge and experience in industrial automation solutions, Cannon Automata focuses on programmable automation controller and fieldbus applications.